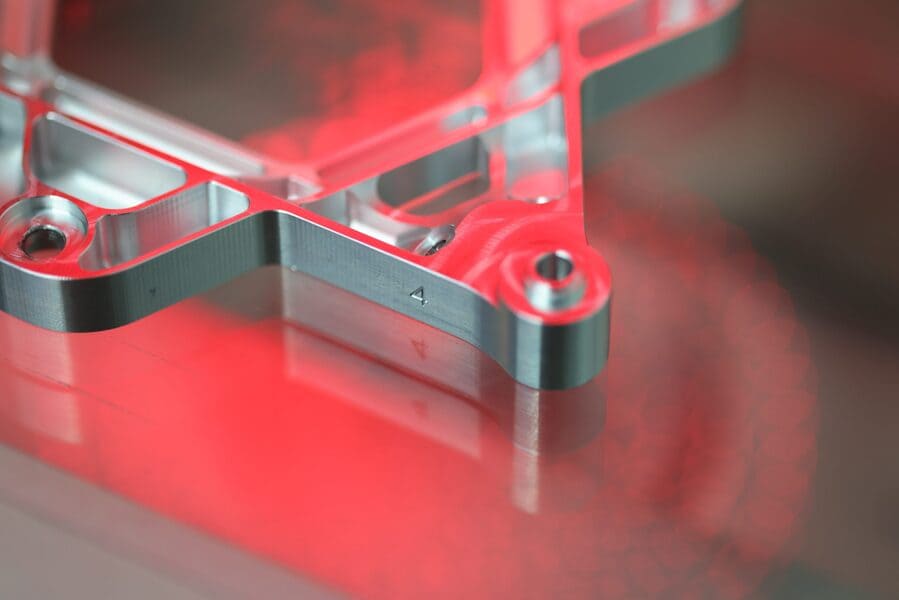

UNE PHILOSOPHIE DE LA PRÉCISION DANS LES RÉALISATIONS TECHNIQUES

Nos métiers de la précision

Pennacchiotti a construit une démarche d’intervention globale dans la mécanique de précision en assurant la gestion de projets de l’amont jusqu’à la fabrication et l’assemblage de pièces usinées.

L’usinage de pièces est une discipline exigeante dans l’industrie de pointe.

Nous étudions chaque projet d’usinage en respectant toutes les contraintes du secteur avec une qualité de précision optimale.

L’accompagnement de projet d’usinage

Aide à l’innovation en mécanique de précision.

Respect des délais et synchronisation de la planification industrielle.

Coordination des acteurs, des moyens de production

et de contrôle de précision.

L’usinage de précision

Usinage de pièces tous matériaux.

Prototypes et séries en mécanique de précision.

Parc machine récent dédié à la mécanique de précision.

Notre dimension projet

dans la mécanique de précision

Pennacchiotti recherche des solutions industrielles innovantes et optimales dans sa conduite de projet.

Nous appliquons une stricte gestion du temps et des délais.

Nous attachons une grande importance à fournir un accompagnement dynamique et flexible car ce sont les ingrédients qui cimentent le relationnel dans l’usinage de précision.

Analyse du projet en mécanique de précision

- Compréhension du besoin en mécanique de précision et du dossier technique.

- Calendrier des étapes du projet, de l’industrialisation à la production, PIC, PDP.

- Choix des matières et matériaux, métaux, céramiques, plastiques, autres.

- Accompagnement dans l’innovation en matière de précision.

Ingénierie du process industriel

- Sélection des solutions en mécanique de précision, fixation des gammes de fabrication et anticipation des montées en cadence de la fabrication des pièces.

- AMDEC, analyse de la valeur et étude de la production par lots pour la montée en cadence industrielle.

- AMDEC process pour la parfaite adéquation des moyens aux exigences industrielles fixées.

- Planification des phases d’usinage et ordonnancement.

Maîtrise de la Qualité

- Opérations de contrôle et de vérification des pièces le long du flux de production.

- Relevés et documents de suivi Qualité de surveillance et la correction immédiate des écarts.

- Suivi des processus Qualité et garantie de la traçabilité des pièces.

- Fourniture éventuelle de certificats Qualité officiels des étapes-clés du cycle de production.

Nous apportons une vision projet aux problématiques rencontrées dans la mécanique de précision.

La mécanique de précision

appelle la précision de l’humain

Pennacchiotti est réputé pour la flexibilité de son organisation ainsi que pour la Qualité et la fiabilité de ses livrables en matière de mécanique de précision.

Ce n’est pas un hasard si les secteurs de pointe de l’industrie française travaillent avec nous depuis plus de 50 ans.

C’est la marque d’une régularité dans la gestion de projet.

L’ADN de Pennacchiotti :

l’usinage de précision

Pennacchiotti est capable de réaliser toutes les phases d’usinage d’une pièce à très haute précision.

Nous adressons des projets auprès de secteurs intransigeants sur la Qualité tels que l’aéronautique, le spatial, l’instrumentation ou l’optique.

Nos pièces usinées garantissent une conformité avec les impératifs de Qualité exigés par nos clients.

Nous disposons des certifications de Qualité qui témoignent de notre expertise en mécanique de précision.

Usinage de précision

Notre parc machine permet des usinages de très haute précision sur tous types de matières. Nous intervenons en sous-traitance industrielle sur des plans d’usinage de pointe 2D ou 3D.

Programmation CFAO en mécanique de précision

Notre capacité dans l’usinage est nourrie d’un investissement fort dans un parc machine récent. Nous portons la précision de l’usinage jusqu’au 3/1000 mm.

Prototypage et préséries industrielles

Du plan industrialisé comprenant les cotations précises et ajustements tolérancés, de la définition de l’outillage à la conception de prototype, nous intervenons sur toute la chaine de valeur de l’usinage.

La diversité de notre équipement machine et nos compétences industrielles permettent une grande liberté d’intervention

pour répondre aux exigences.

Nos atouts

dans la mécanique de précision

50 ans d’expérience dans la mécanique de précision forgent assurément la compétence.

Une offre globale pour la mécanique de précision

Nous intervenons en sous-traitance industrielle pour répondre à l’ensemble des problématiques des secteurs de pointe.

- Usinage, tournage, alésage, fraisage, perçage, découpe au fil et enfonçage par électroérosion, rectification plane

- Usinage de pièces métalliques, Inox, Aluminiums, Molybdène, Titane, Invar, Kovar, Mumétal, Nitinol, Tantale, alliages Ni, alliages Mo, Alliages Ti, Alliages de Tungstène…

- Usinage de pièces thermoplastiques, thermodurcissables et élastomères, tels que PEEK, PET, PETP, PEAD, PE, ABS, DELRIN POMC, PTFE, PMMA, PA, PVDF, ERTALYTE, PVC, VESPEL, TORLON, ERTACETAL, …

Une grande réactivité dans la conduite du projet

Nous avons voulu combiner la flexibilité d’une entreprise à taille humaine avec la capacité technique d’un groupe.

- Ingénierie de projet complexe en mécanique de précision

- Innovation, assistance à la conception et prototypage de précision

- Maîtrise des délais et interlocuteur unique

Nos domaines d’intervention

Nous intervenons dans les domaines de la haute précision industrielle.

Domaine de l’équipement de précision

Micro-électronique, Aéronautique, Militaire, Laboratoires de recherche, Aerospatiale, Energie, Nucléaire, Hydraulique…

Domaine de l’outillage et de la machine

Optique et capteurs industriels, Mécatronique, Véhicules et motorisation, Turbines à haute vitesse…

Domaine des instruments de précision

Lasers, Capteurs de mesure et d‘observation, Caméras, Appareils de mesure, Sous-ensembles complexes…

Notre philosophie de l’innovation

Une demande est toujours un besoin technique qui appelle un métier d’expert.

Nous attachons une grande importance à la compréhension de la demande. En tant que professionnels de la précision, nous coordonnons les métiers de l’usinage dans le respect des impératifs de Qualité et des livrables.

L’innovation est pour nous le moyen d’anticiper la demande tout en faisant grandir nos métiers. C’est une vision du marché et une manière de concevoir la fabrication sous l’angle du service.